The challenges facing the food industry are particularly high in the areas of hygiene, temperature, and logistics. A high-speed door helps make production and storage requirements more efficient and safer.

Walking through a supermarket in Germany is like walking through paradise. Shelves bursting with food in all shapes, colors, and varieties. Fruit, vegetables, pasta, fish, meat, canned goods, and sweets are just a small part of what is on offer.

In 2025, the food industry in Germany will deliver an impressive variety for all consumers – despite the many daily challenges in production. These become clear when you take a look inside the production hall.

Very high hygiene standards prevail there in order to maintain consistent food quality. In addition, there are temperature specifications that must be strictly adhered to so that food remains fresh throughout the entire production process.

Industrial doors are an important component in food production

Industrial doors play an important role in maintaining hygiene standards and constant temperatures. They strictly separate production rooms or storage facilities with different requirements. This enables smooth and fast processes despite different temperature specifications.

The global market leader for industrial high-speed doors, EFAFLEX Tor- und Sicherheitssysteme GmbH & Co. KG, optimally meets the requirements of the food industry with its door systems. This is because all doors from this premium manufacturer are synonymous with high door speeds, optimum airtightness, and enormous durability. “EFAFLEX offers the food industry an all-round carefree solution with its high-speed doors,” says Christian Oberpriller, food industry owner at the door manufacturer.

BVLK recommends EFA-SRT® EC as the only hygienic roll-up door

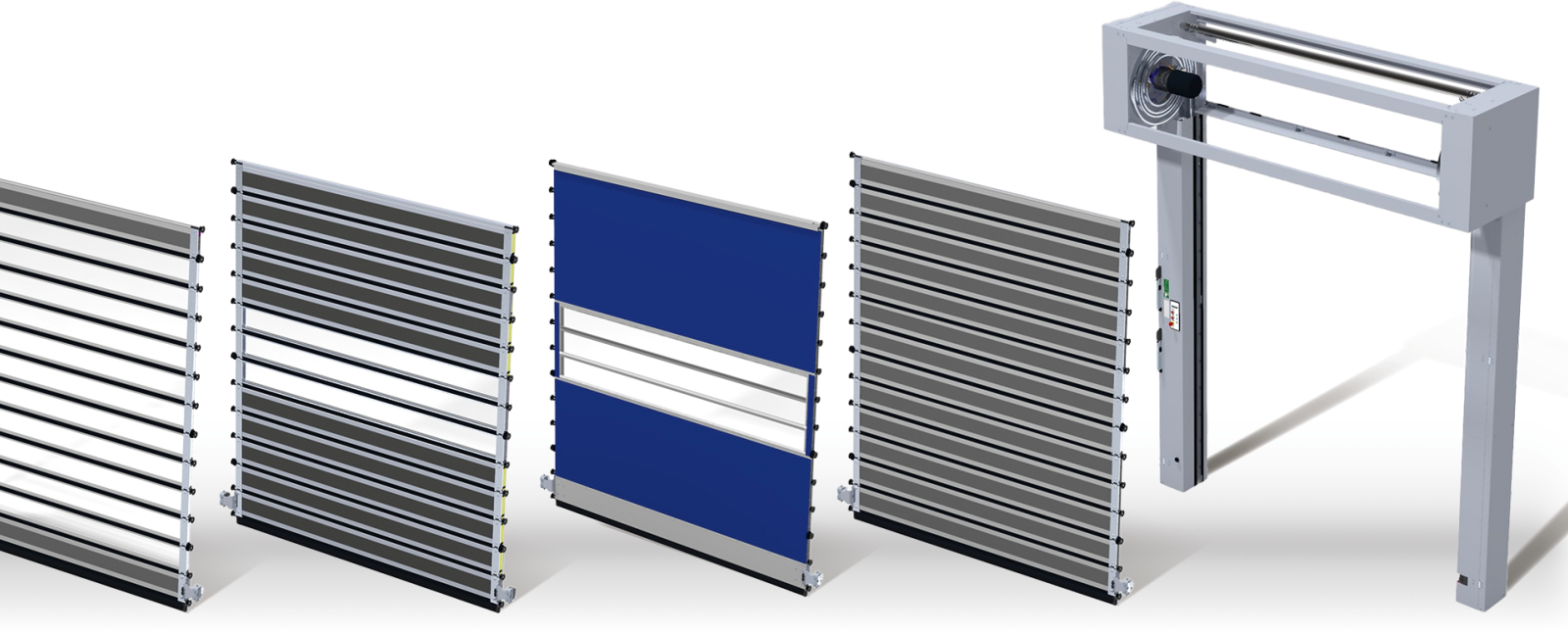

The EFA-SRT® EC, a high-speed roll-up door with the letters “EC” standing for “Easy Clean,” is often used in the production areas of processing plants (meat, fish, etc.).

Easy cleaning of the door is extremely important in order to meet the hygiene standards that must be observed when cutting meat, for example. The “Easy Clean” scores highly here with its basic design featuring a washable curtain and hinged stainless steel frames.

“All covers can be easily opened to enable hygienic cleaning after work processes. Liquids can drain away unhindered thanks to the sloping design of the winding shaft cover and the endshield,” says Christian Oberpriller, explaining the other advantages of the high-speed roll-up door. No wonder, then, that this door is the only hygienic roll-up door recommended by the German Federal Association of Food Inspectors (BVLK).

Can also be used in confined spaces

In confined food production spaces, the EFA-SRT® EC also scores points with its space-saving design and can withstand even the highest loads with up to 150,000 load cycles per year. The opening speed of up to 2.0 m/s accelerates logistics processes throughout production.

Food production volumes can also be further increased if logistics processes are more efficient and faster.

Depending on the product storage requirements, there are a wide variety of applications and environmental situations for a door system. Whether for a blast freezer, a cold storage and deep-freeze warehouse, or an automated high-bay warehouse, EFAFLEX delivers customized door solutions. In deep-freeze warehouses in particular, the reliability of the storage equipment is essential for smooth logistics. Sophisticated solutions in conjunction with conveyor technology are also essential.

Innovative sealing systems prevent the exchange of air masses

The most important factor is basic tightness to prevent air exchange when closed and, as a result, condensation in the refrigeration or freezer area. “EFAFLEX industrial high-speed doors are particularly well insulated thanks to their design and are therefore ideally suited for use in temperature-sensitive areas,” says Christian Oberpriller.

The high door speeds of EFAFLEX high-speed doors, combined with sophisticated additional systems, enable resource-saving operation. The open holding times are reduced to a minimum, which reduces the exchange of cold and warm air masses, leading to energy savings.

This is also a relevant issue for cold rooms up to 0 degrees Celsius. These are often used to store perishable foods such as fish, meat, or cheese in order to inhibit bacterial growth. At the same time, cold rooms must not be overfilled, as this reduces the cooling capacity and could damage the products.

Insulating laths and high-speed spiral door technology combined

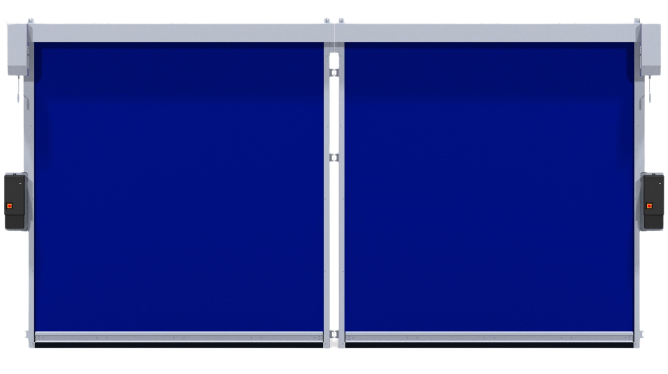

With the EFA-SST® ISO-60, EFAFLEX offers two technologies in one high-speed door. On the one hand, there is the high-speed spiral door technology invented by the company and, on the other hand, the double-walled EFA-THERM® insulating laths, which enable a U-value of up to 0.8 W/m²K.

A door speed of up to 2.5 m/s further contributes to the success of logistics processes in cold rooms and reduces the exchange of air masses.

The requirements are even greater in the deep-freeze area. Here, the deep-freeze temperature must be maintained at all times; only for the duration of transport, for example between the warehouse and the supermarket, may a maximum of +3 degrees be reached. Another challenge arises when a door is opened in a deep-freeze area. Warm air flows in and rises towards the ceiling of the room. This leads to condensation of the incoming air humidity and subsequent icing of metal parts, such as the door spiral. The door would no longer be operational.

The EFA-SST® TK-100 high-speed freezer door meets these demanding challenges, even as a single-door solution. “The requirements of customers in the food industry led to the development of this door,” says Christian Oberpriller.

EFA-SST® TK-100 features a patented sealing system

The door leaf of the high-speed door solution for deep-freeze areas is equipped with 100 mm thick EFA-THERM® laths, and the door system impresses with its innovative design. The door has a circumferential profile seal and flexible door leaf guidance. The guidance is mounted on the frames and the spiral mount in a way that allows it to be moved. When closed, the door leaf is moved toward the frame by a patented active guide rail mechanism and, in combination with the profile seal, closes the room almost hermetically.

This results in a value of 1.5 m³/m²h, meaning that the EFA-SST® TK-100 achieves air permeability class 5 in accordance with DIN EN 13241 and a U-value of 0.62 W/m²K. The all-round seal of the door system, similar to a refrigerator door, can also be used to seal off oxygen-reduced storage areas.

With up to 200,000 load cycles per year and a door speed of up to 2.0 m/s, the EFA-SST® TK-100 offers an impressive range of applications in the deep-freeze sector.

Extensive accessory solutions further improve processes

However, fast, reliable, and airtight doors alone are not enough in food production. Sensors, collision protection, and other accessories improve logistics processes in combination with high-speed doors. Innovative solutions from EFAFLEX, such as the EFA-3D-SCAN®, which uses a three-dimensional safety field to open the respective door according to the situation and requirements, make processes involving the door even faster and safer.

The EFA-SmartConnect® app controls and monitors all door systems simultaneously, including a direct connection to the company’s own service department. The EFA-SmartAssist® digital remote maintenance tool also provides immediate and rapid assistance. Experienced and trained in-house employees assess the requirements via video link and provide direct assistance or promptly send trained service technicians to minimize downtime and idle time.

High-quality, tailor-made solutions

EFAFLEX offers sophisticated high-speed door technology, efficiency-enhancing assistance systems, and comprehensive door services from a single source. The company provides multifaceted and customized solutions that are tailored to the customer’s needs.

Because at EFAFLEX, “fast and safe doors” is not just the company slogan, but also a promise to customers and their requirements. This will make walking through the supermarket aisles even more enjoyable in the future.